FEMFAT MELCOM

Electronic Computation

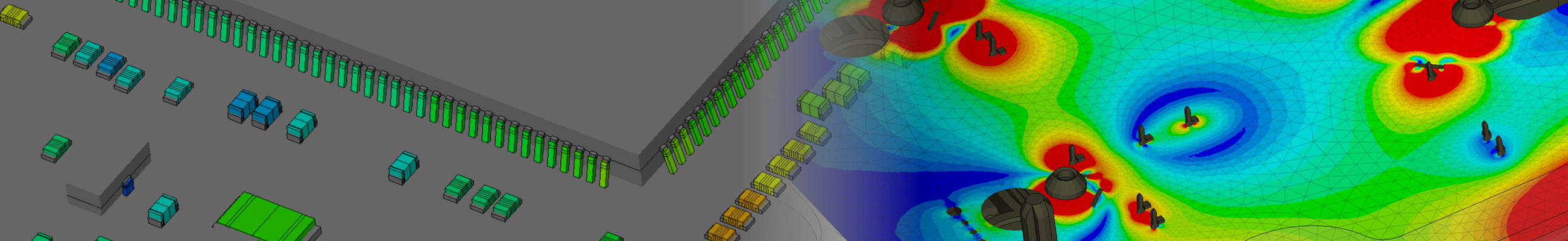

Structural Reliability Analysis for Electronics

Get in touch

All about FEMFAT MELCOM

Electronics have become an integral part of our lives. In particular, electronics is an indispensable factor in data processing, communication and are now taking over mobility as well. The trend towards electrification of the powertrain requires the development of electronics or power electronics that can withstand a variety of loads. Specifically, static deformations due to tolerances in the mounting points, time-dependent mechanical excitations of all kinds (sinusoidal, stochastic, or shock-like excitations), and thermal stresses must be taken into account. Depending on the type of load case, different failure phenomena can occur. Tolerances in the mounting points can lead to the fracture of sensitive electronic components (Multi-Layer Ceramics Capacitor - MLCC) due to excessive deformation in the printed circuit board (PCB). Vibrational or shock loads, if not properly designed, can cause cracks in solder joints and result in defective signal processing. The alternation between hot and cold environmental conditions, if not adequately considered, can result in cracks in both the PCB and the solder joints as well. To assess a robust design and the suitability of electronic development already in the virtual world, FEMFAT MELCOM offers you the opportunity to analyze your electronic design for the mentioned failure modes. This provides you a mechanically secured design of your electronics, as well as robust prototypes and reduces thereby development times in hardware creation.

Learn more

Benefits

Structural evaluation of PCBA (printed circuit board assembly) in an early design phase:

- Solder Joint Fatigue

- Chip Crack

- Thermomechanical Analysis

Highly automated process steps

- Fast FE model generation using ANSA

- Automated detailed meshing based on ECAD data (ODB++, layers, traces, vias, drill holes)

- Automated FE model simplification (homogenization of PCB material enclosed in finite elements)

Link between electronics development and structural analysis

- Direct processing of electronic design data

- Automated preparation for damage analysis with FEMFAT for Solder Joint Fatigue

- Large extendable database with separate modelling process for SMD components and solder joints